Standards of maintenance for certificates of STS fenders and hoses

26-09-2022

|

|

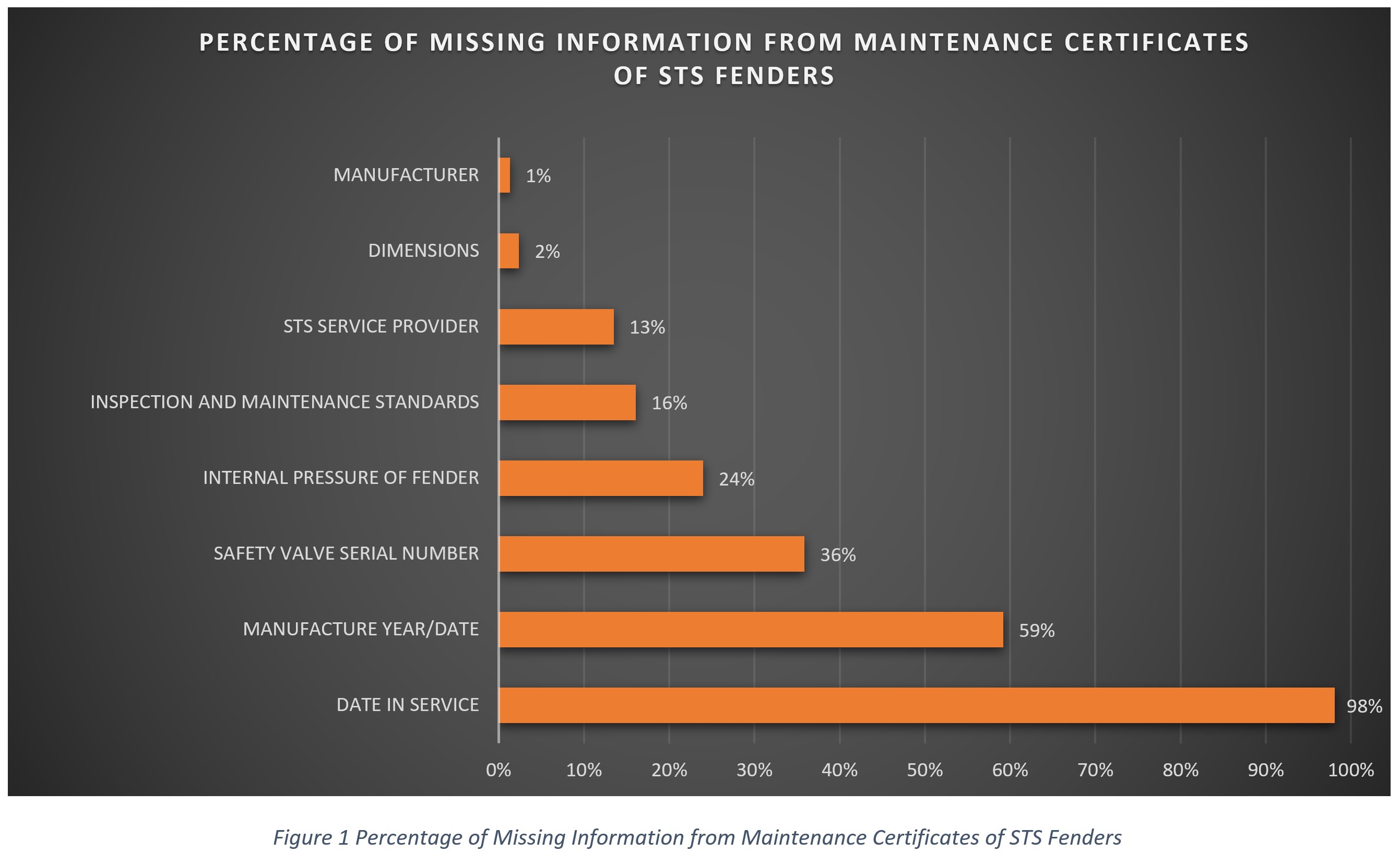

Article Anna Giannakaki, Ioannis Liarokapis, Alexandros Glykas, DYNAMARINe The role of the STS Service Provider in an STS operation is considered of paramount importance. As stated in the latest STS Transfer Guide in section 2.5, p.17 If an STS service provider is employed, the quality of the services and equipment provided are paramount if operations are to be carried out safely, reliably, and efficiently. In this respect, to verify that the STS equipment is in line with the international standards, DYNAMARINe has utilized the information which was extracted through the STS equipment database. This database contains information on certificates of fenders and hoses which DYNAMARINe received through the assessment process of the STS equipment DYNAMARINe process the data in order to extract trends and lessons learned in order to improve the safety standards amongst global STS Operations. It is not our intention to develop a blame culture since there are no existing standards related to the information conveyed through maintenance certificates of STS gear Maintenance certificates are used as a sample in this statistical analysis in order to ensure conformity with the best industry practices and to verify the integrity of the STS equipment. Based on experience so far, and best industry practices, DYNAMARINe has concluded on the minimum information needed to be included in the maintenance certificate. There is a need for transparency in the maintenance of STS equipment and how the SMS processes of STS Service Providers are unequivocally reflected in the maintenance certificates. In this way, our industry will isolate substandard practices and will minimise the risk of a pollution The output of this analysis can be summarized in two figures as included here below. Each figure contains the list of information that is considered crucial and should be included in each STS equipment maintenance certificate. For each type of information, a percentage has been calculated. This percentage corresponds to the number of certificates that did not include this information category. Separate figures have been generated for fenders and hoses. The first part of this analysis is related to the fender certificates. In Figure 1 below, one can locate which information is vital with regard to the accuracy of information as far as a maintenance certificate is concerned. Overall, the amount of information that is omitted from the maintenance certificates reflects whether the company has a solid maintenance system, and it is an indicator of whether the company complies with international standards. Although a company may undertake the maintenance of an STS gear properly, this has to be transparently reflected in the maintenance certificates As it was observed, the safety valve serial number of a fender is of major importance. In case the original certificate's safety valve changes, the maintenance certificate should be updated to incorporate the new safety valve number, since it affects the date of inspection schedule, according to the latest guidelines of the manufacturer. More than one third of certificates were missing this type of information.

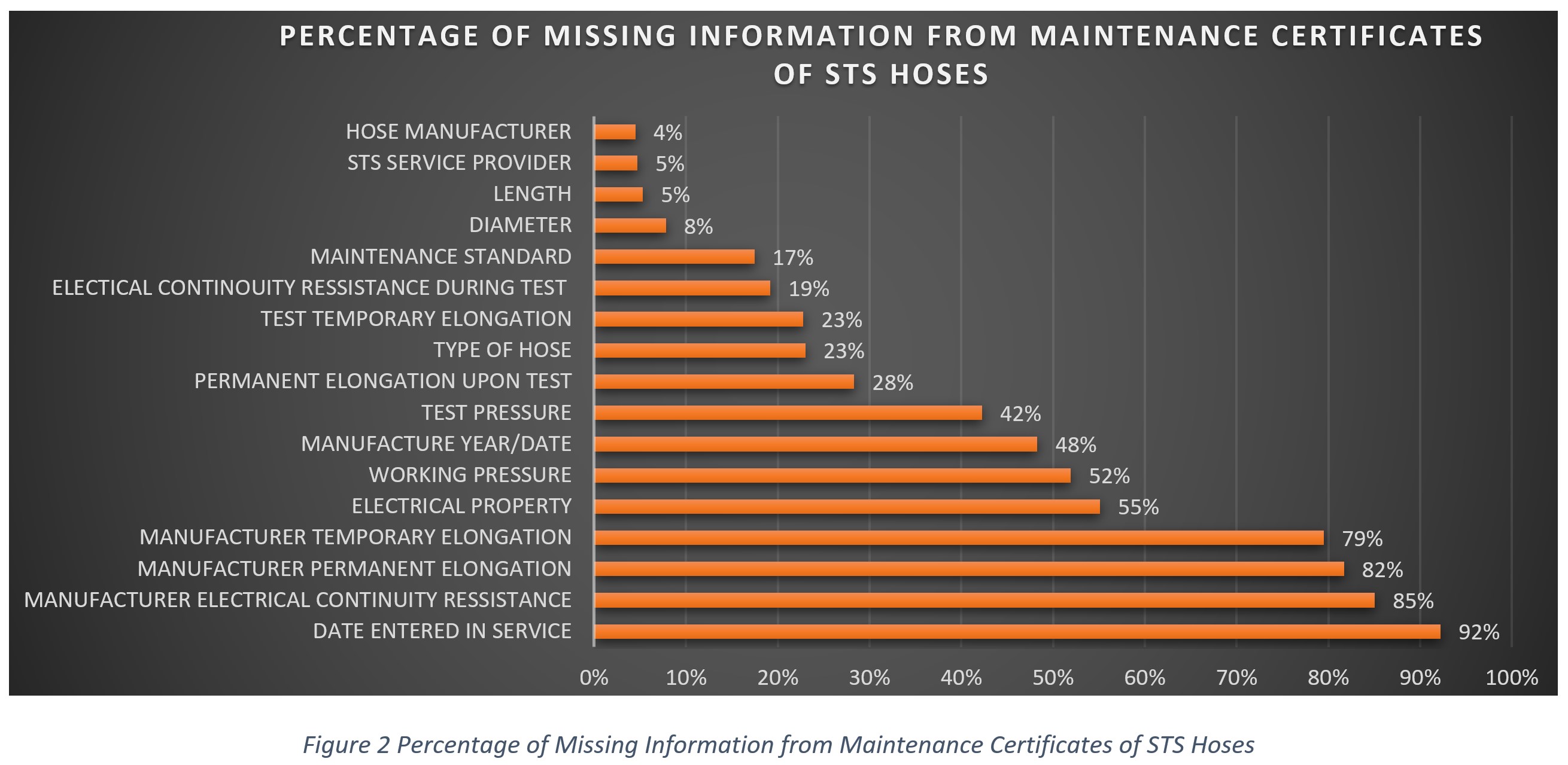

Additionally, the date of manufacture of the fender holds great significance. It should be reflected on the certificate, as it can denote the retirement date of the fender. As per the latest STS transfer guide chapter 9.1.3, p.75 'fenders should not be routinely used beyond the manufacturer's recommended service life, which will typically be 15 years'. The same applies to the date of entry into service. Considering that the equipment can be purchased and stored in warehouses before utilization, the date in service ought to be mentioned in a maintenance certificate. Great emphasis is placed on hoses, which are a substantial component of the STS operation since they are directly related to the transfer of cargo and play an important part in the prevention of oil pollution. The second part of our study investigates whether the hose certificates are in accordance with best industry practices and guidelines. According to ISGOTT, the minimum data in an STS certificate are specified. This set of data is included in the left column of Figure 2.

DYNAMARINe has observed that there is a tremendous inconsistency when it comes to the hose manufacturer standards, resulting in an increase of the shipowners' liability which can difficult be mitigated a few hours prior to the actual operation. Service providers should take the necessary steps to ensure that the information provided in the certificates is precise and accurate, while simultaneously proving that they are complying with the best practices and guidelines of the manufacturers. The shipowner in his turn, should not accept hoses, whose maintenance information is not transparently shown in the relevant certificates. As per the manufacturer's recommendation, the usual storage and service lifespan of a cargo hose can not exceed 10 years. However, the service life of a hose is lower than the storage and fluctuates between 4 and 6 years, depending on manufacturer retirement criteria. This period is subject to proper hose handling. In this respect, since the storage life differs from the service life, it is considered that the date of entry into service is critical information in order to ensure transparency along with proper maintenance of the hoses as per the manufacturer's recommendations. In addition, data related to the elongation limits (permanent and temporary) as well as electrical continuity characteristics is also considered important in the maintenance of the hose and should be included in each maintenance certificate. To sum up, it was observed that the hoses certificates lack much more significant information compared to the information conveyed through the fender certificates, with the date entered in service being the type of information missing in most of the certificates. At fender certificates, fewer types of information are required in comparison with types of hoses. In light of the above comparison, it was concluded that the hoses certificates lacked the most information in percentage through the review by DYNAMARINe, having in mind that these certificates must include numerous types of information for them to be considered adequate. As advice to STS Equipment owners, we recommend that the following information should be included in the maintenance certificates either of fenders or hoses. Information that should be included in the Maintenance Certificates of STS Fenders is the following:

Information that should be included in the Maintenance Certificates of STS Hoses is the following:

For further information, please feel free to contact DYNAMARINe at info@dynamarine.com |

DYNAMARINe Team

2 ARKADIAS AND 125 GOUNARI STR, Glyfada 16561, Greece, T:+65 31590353, +302109628379, E:info@dynamarine.com