Industry Best Practice in Ship-to-Ship

18-01-2022

|

|

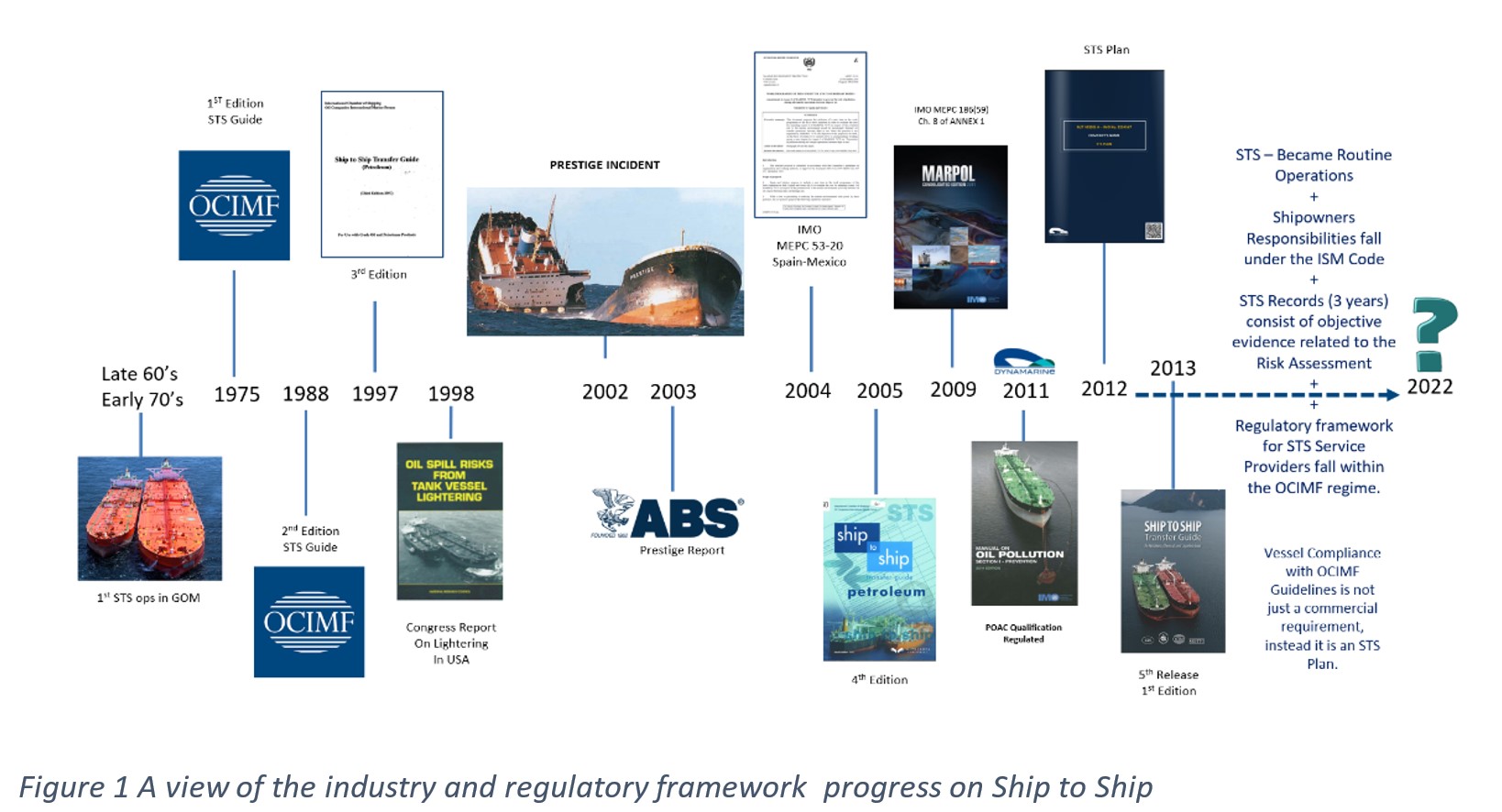

Industry Best Practice in Ship-to-Ship A Learning Process through Management Systems Alexandros Glykas, DYNAMARINe Over the last decade, DYNAMARINe has collected, observed, and verified firsthand assessment data from Ship-to-Ship transfer operations. Apart from providing a service to clients, these assessment data are being processed in order to produce the likelihood of events and lessons learned, which consist of a source of information that we call, Industry Best Practice. Safety standards are not stationary; on the contrary, their developments are subject to continuous improvement, as the information from previous incidents or near misses are reported. Besides, the development of safety standards depends on the applicable systems of the existing industry infrastructure without of which, any safety-related information would pass unattended, thus unassessed, with zero contribution to further improvement. So, how can one measure the progress of safety standards, and what are the ingredients of Industry Best Practice in STS operations? These are only two but are functional questions on how the progress on safety standards could be assessed. Apparently, when we use the term Best industry standards we indirectly refer to the up to date safety standards that ensure minimum risk. Industry partners have available means of communicating best industry practices such as the OCIMF STS guide, as amended from time to time, supplemented also by SIRE recommendations. Other means of communication are the STS Forums, such as the ITOL, SNI, EMEA, IFSTS, where STS Service providers and tanker owners discuss incident-related information, other findings, and lessons learned. Progress Figure 1 shows the progress on STS industry and statutory regulations, following a path of experiments, knowledge, incidents, investigations, and new ideas.

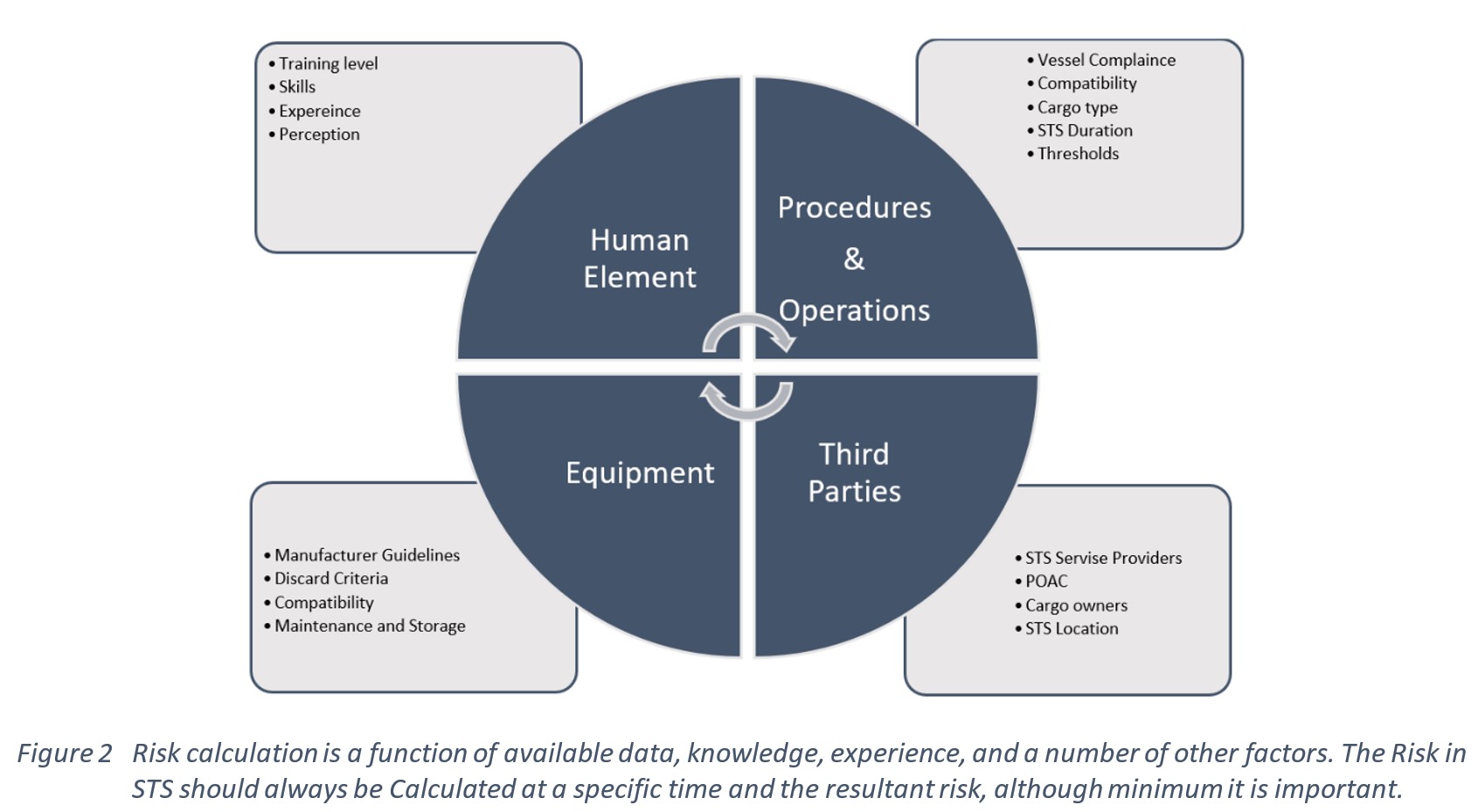

Ship-to-Ship is another shipborne operation which has still a way to go for improvement. Although shipowners should follow the Best Industry Practice as a process which ensures minimum risk, in order to be in compliance with the ISM code, the remaining risk (resultant risk) will always be unknown and uncertain One way to explore the resultant risk is through the observed incidents in various STS operations. But again, this would be indicative and subjective since the risk is a function of knowledge, experience, competency, conditions, STS location, type of trader, STS Service provider, and SMS System quality. Therefore, one way to progress towards extracting objective findings is to collect all those subjective findings and consolidate them under a unified process We all have heard the phrase I have done 2000+ STS Operations said by experienced master mariners, either mooring masters or ship masters. This phrase aims to indicate experience. But how beneficial is that experience to 3rd parties conducting STS Operations globally, if all 2000+ STS operations have taken place in specific locations such as Augusta in Italy, or the Gibraltar Bay. How is this STS experience comparable to the experience of a Mooring Master with 500+ STS Operations from 20 or more different STS locations globally? I would prefer the 2nd option, even if the total number of STS operations is substantially lower than the first one. Therefore, establishing experience in numbers is not indicative and should be assessed with care. There are qualitative characteristics behind each STS operation In a similar way, Best Industry Practice as known today relates to findings known and assessed till now. Tomorrow is another day with new challenging experiences that require our attention and careful approach. Therefore, the tool towards ensuring safety, is not only related to the application of the Industry Best Practice. It additionally depends to the mechanism, i.e., a management process to be able to identify all potential and even unknown threats. This process requires input from the following tools:

These are the most prevailing means which can identify new opportunities for improvement of Industry Best Practices in STS operations Requirements Basis on the bullet points presented in the preceding paragraph, shipowners need to identify through their regulatory obligations, the level of compliance along with probable commercial exposure The application of revised (International Maritime Organisation SOLAS 74/78, 2008) regulated the Shipowner's requirement for raising safeguards against all identified hazards. Indirectly the ISM requirement mandated the development of a risk assessment; as simple as that! Taking into consideration that the risk equals likelihood times consequence, once the consequence is quantified, the unknown parameter in the equation is the likelihood, and this is the difficult part.

Regulators of the relevant working group at the IMO, along with OCIMF, have identified that the likelihood would be possible to be defined only if STS records could become available somehow, from shipowners. For this reason, we believe that it was decided at the relevant MARPOL regulation that STS records should be retained for three years. Since records are available, they should be processed further and produce the likelihood for the Risk Assessment. OCIMF in a very ambiguous decision, even from the previous version of SIRE, has recommended what those STS records should be in a list of documents with importance of their use and application, especially when claims are brought before an arbitration STS Plan vs Risk Assessment In many instances I have wondered about the innovation on the requirements mandated from MARPOL chapter 8 of ANNEX I, ratified in 2009. What was its real impact? Although the STS Plan appeared to be something new, was that the impact? The answer is simply: There was no impact. Although the STS Plan was a new requirement, it was not the breakthrough of the regulation since most inclusions were already a requirement of the ISM. We have a concrete view that is summarized in the following points:

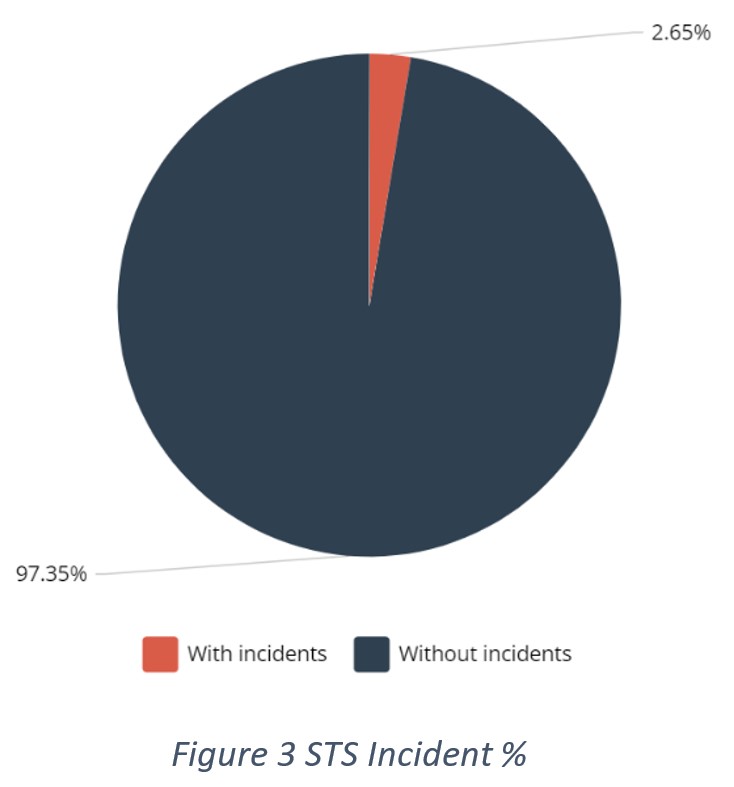

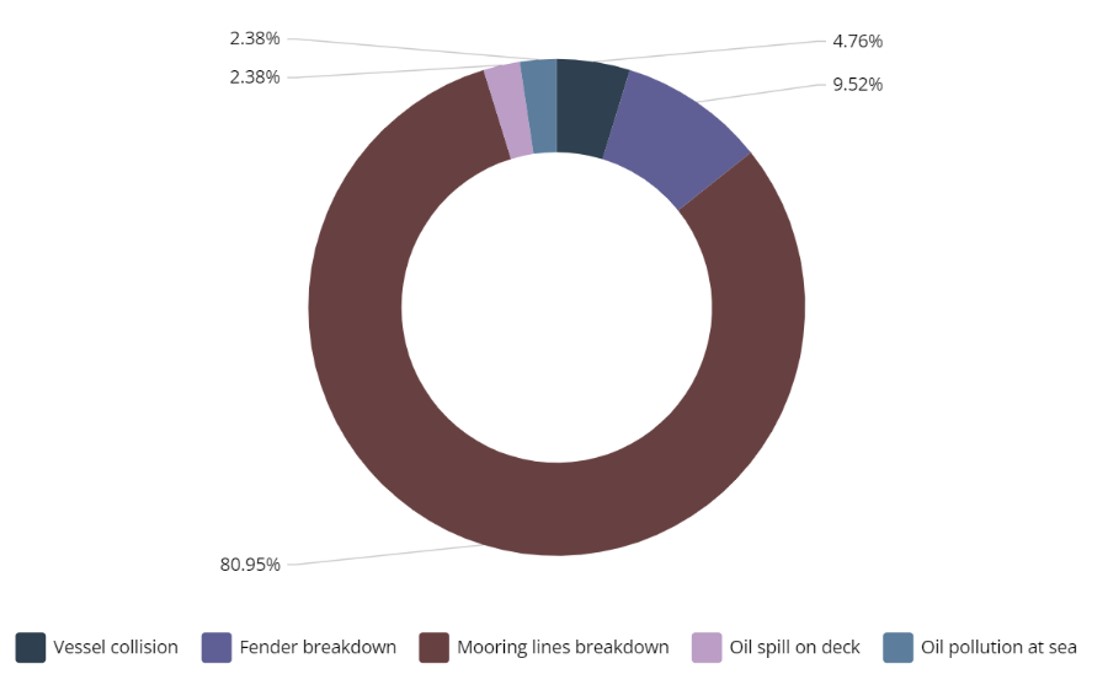

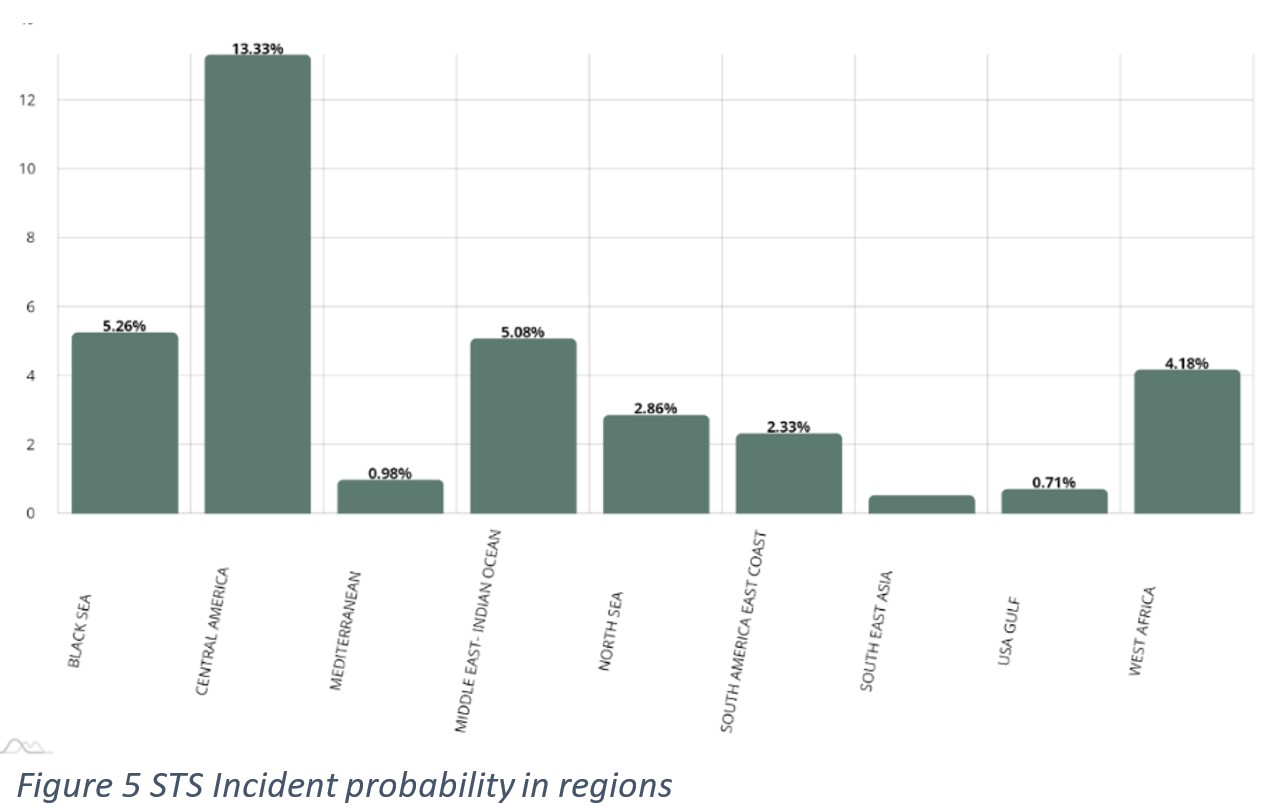

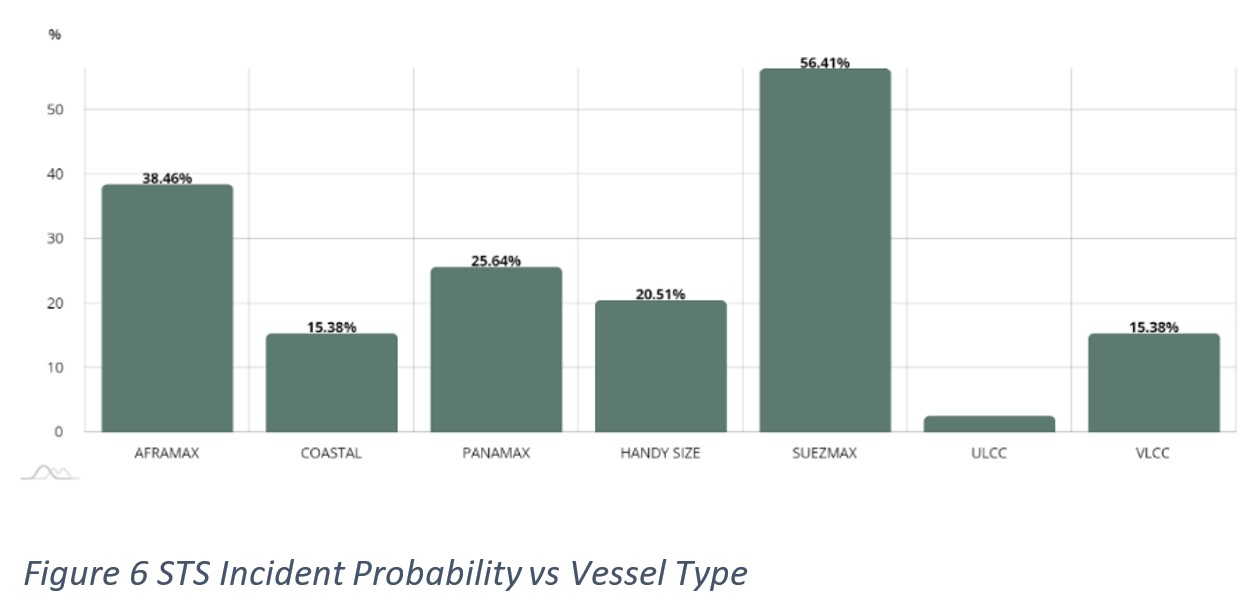

Focusing on the latter, the STS Plan is developed on the basis of the latest OCIMF STS guidelines. At the ANNEX K of this reference, there is a number of causal factors presented. Therefore, since this guide is the current best practice, the shipowner has the obligation,to safeguard all identified risks, full stop. Any deviation of the risk assessment from the best industry practices could be deemed as a violation of the regulation or lack of duty of care. The vessel compliance with respect to OCIMF guidelines is partially reflected through the STS risk assessment. For a long time now, DYNAMARINe campaigns that a vessels' risk assessment should be reviewed to be in line with best industry practices. Our opinion is that any deviation from this process hinders risks with potential exposure to ship owners Conclusion Industry best practices in STS are always subject to change as the information from assessments flows. The applicable regulatory and commercial infrastructure is adequate to accommodate improvement Ship owners need to focus on the risk assessment, collection, and assessment of the STS record process, assign resources and available means in order to assist their compliance and minimize potential exposure. Relying only on own resources either doesn't make sense or in most times provides limited value to the organization, while increasing the burden of shore staff DYNAMARINe Role The STS Screening and Risk Assessment service of DYNAMARINe originally aimed in assisting shipowners towards fulfilling their obligations against statutory compliance. As time went on, we realized that this tanker sector needed more than a service. It needed an opportunity, emerging from the shipowners, to assist on the improvement of the industry standards, as the number and opportunities of STS operations grown around the globe either in number or new unknown STS locations. This sector has shown that it has the means to produce knowledge and improve, however such source of information has not been originated from Shipowners, until DYNAMARINe introduced the sharing of STS information That was, and still is the impact of DYNAMARINe as it continues to support STS operations with the provision of data. During the last two years, we also have the increased capacity to produce opportunities for interactive training for seafarers The Master of the ship is the most senior in the hierarchy and experienced seafarer on board the ship. His post feedback assessment is a must for the technical operator as well as the Cargo owner related to the cargo transferred via STS. This Post feedback is the core information for improving safety standards and to reduce incidents in future operations Indicative Statistics DYNAMARINe is an STS data provider along with an STS assurance organization and a training academy. We consider that it is our duty to disclose statistics openly on Ship to Ship as reported each year to OSIS.Upon consolidation of data from OSIS, we shall revert with a dedicated annual report on STS statistics before April 2022 Figures 3 to 6 below present only a few, however important diagrams of STS Incident-related findings from a sample of 1720 unique STS operations conducted during 2021

The total observed STS incident % is 2,65%. This means that almost 3 out 100 STS Operations will be involved in an incident amongst those depicted in figure 4

Figure 5 depicts how the incident probability is distributed in global regions and figure 6, how the incident probability is distributed amongst vessel types

It seems that the most critical combination in STS is a Suezmax vessel performing an STS operation in Central America. [1] Industry Best Practice means, in relation to any services, the exercise of the skill, diligence, prudence, foresight and judgment which would be expected from a highly skilled and experienced and well-resourced person engaged in the same type of undertaking under the same or similar circumstances, applying the best standards and practices currently applied in, as the circumstances require, the relevant industry. ReferencesDYNAMARINe. (2021). OSIS STS Statistics 2022. Athens: DYNAMARINe. ICS/SIGTTO/OCIMF/CDI. (2013). Ship to Ship Transfer Guide for Petroleum, Chemicals and Liquefied Gases. London UK: Witherby. International Maritime Organisation SOLAS 74/78. (2008). RESOLUTION MSC.273(85). AMENDMENTS TO THE INTERNATIONAL MANAGEMENT CODE FOR THE SAFE OPERATION OF SHIPS AND FOR POLLUTION PREVENTION (INTERNATIONAL SAFETY MANAGEMENT (ISM) CODE). London: IMO. International Maritime Organisation MEPC 186(59). (2009). CHAPTER 8 PREVENTION OF POLLUTION DURING TRANSFER OF OIL. London: IMO. London Arbitration Courts. (2018, 02). AMPTC vs LITASCO. Retrieved 11 02, 2019, from http://bit.ly/31WCaLe OCIMF. (January 2022). SIRE 2.0 Question Library Part 2 Chapters 8 to 12 Version 1.0. London: OCIMF. Retrieved from https://bit.ly/3521pBq Oil Companies International Marine Forum. (2019). VIQ-7, Ship Inspection Report (SIRE) Programme. London: Oil Companies International Marine Forum. For further information please feel free to contact DYNAMARINe at info@dynamarine.com |

DYNAMARINe Team

2 ARKADIAS AND 125 GOUNARI STR, Glyfada 16561, Greece, T:+65 31590353, +302109628379, E:info@dynamarine.com