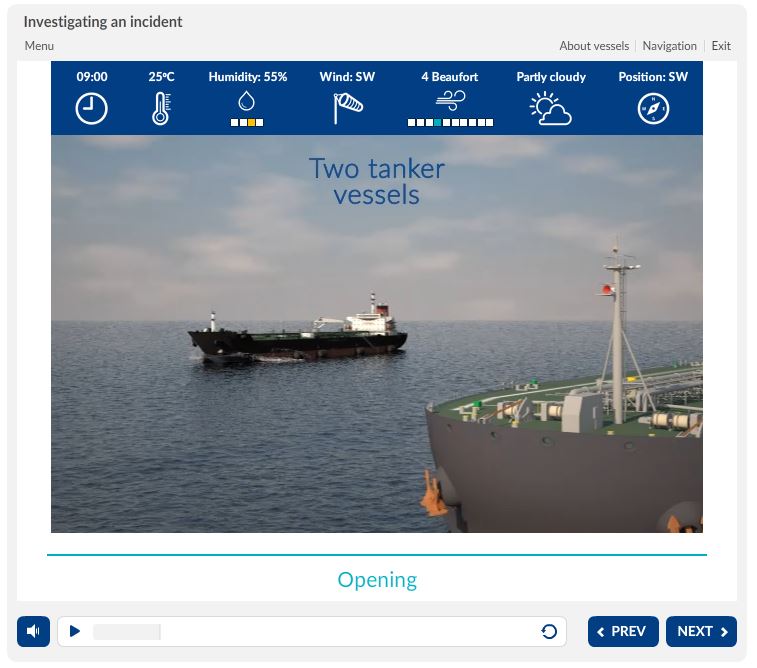

18 STEPS TO PREVENT A COLLISION DURING MANOEUVRING FOR A SHIP-TO-SHIP TRANSFER OPERATION

12-09-2016

?

18 STEPS TO PREVENT?A COLLISION DURING?MANOEUVRING?FOR A SHIP-TO-SHIP TRANSFER OPERATION

It was recently shared by SHIPOWNERS P&I Club, that a number of their members experience a large number of collision claims related to berthing operations during STS. The club had published on 27/01/2015 a bulletin with advises to members on procedures towards ensuring that STS approaching is carefully planned. Nevertheless, the club still experiences a large number of incident claims and recently has shared with its members that a diligent planning should include the club recommendations that were outlined in the billeting of 27 January 2015.

onlineSTS.net considers that the human element is the major factor during the organisation and assessment of an STS operation. By far most important is to follow industry guidelines while simultaneously making sure that all STS stakeholders evaluate and implement industry guidelines with due care. Regardless the level of preparedness a ship owner implements in an STS operation through training, procedures and evaluation, it is important to know that all three involved parties (both vessels and the POAC) act with the required level of preparedness.

The culture of being diligent in the organisation of an STS operation is implied through ?Due Diligence? actions that need to be exercised, primarily from the shipping company followed by well-established and measurable procedures.

Vessel approaching during an STS operation is the first action towards implementing the operation but also denotes that ?proper planning? has been effected prior to engaging to the physical process. Our advice to those involved in the ?proper planning? include the following steps (but not limited to):

1.?Assess the Joint Plan provided by the Service Provider and POAC along with its risk assessment. Latest industry STS guidelines by OCIMF et al. include very useful guidance for Masters, at paragraph 5.2, regarding the assessment of the Joint Plan. If in some occasions the Master is not aware of the Joint plan, he has to request same by the provider and POAC. Reputable STS service providers, announce the Joint plan well in advance of the STS operation. In case the Master has any doubts about the planning of the operation, such concerns should be raised during the assessment of the Joint Plan.

2.?Assess the Parallel body of the manoeuvring vessel and make sure that primary fenders are correctly positioned. First and last primary fenders should be placed by the end of the parallel body. Develop a simple drawing on the basis of vessels? mooring plans. Assess also the proposed mooring plan and discuss any concerns with the POAC.

Proposed fendering and mooring diagram, as planned prior to the operation by the Master or STS organiser

3.?Assess the position of the secondary fenders. Those should be positioned after the ends of the parallel body at a height that is relevant to the vessel with the lower freeboard. In case there is no chock available for the suspension of the secondary fender, consider the use of portable chocks. Service providers have the capacity of supporting you with the provision of a portable chock.

?Fender Vertical Position should be assessed with respect to the lower freeboard of participating vessels

?Improper placement of Secondary Fender

4.?Assess that the scheduled fenders are adequate for your STS operation. You should evaluate fenders on the basis of latest industry guidelines. Assess the berthing energy of the manoeuvring vessel and compare this with the fender energy absorption. Extract the safety factor of the fender, which should be well above 1 and therefore assess the maximum anticipated lateral berthing velocity.

5.?Assess that fenders are properly maintained according to industry and ISO requirements. Fender certificates should be provided along with the JPO. Remember that fenders should be manufactured according to ISO 17357 and that safety valve should be overhauled (maintained every 2 years). In consecutive STS operations, when fenders have been deployed in the field for a prolonged time, it has to be ensured that fenders have not lost any internal air pressure during previous STS operations.

6.?In some locations and especially in STS operations without the employment of TUGS, the first primary fender may need to be secured with an additional safety guy rope, further to the pennant mooring wire. This will prevent fender dislocation; in case the wire fails.

A 2nd safety pennant rope deployed for the first Primary Fender, on the manoeuvring vessel

7.? In consecutive STS operations, where fenders have been placed on the constant heading vessel, attention is drawn to the RISK assessment that has been developed. Latest industry guidelines make explicit reference to this issue. This should include but not limited to provisions for risk mitigating measures and safety thresholds associated with proper placement of fenders on the basis of the parallel body of the manoeuvring vessel. The risk assessment developed by the service provider should account for such causal factor.

8.?Ensure that the participating (manoeuvring) vessel does not have any pending class conditions or recommendations that may affect her performance in the STS operation. Related issues could be associated with her steering, A/E generators, dislocated chocks etc.

9.?In case of TUG boat employment, it is recommended that their power is fit for the purpose and that good communication protocols have been established. Working language should be uniform and clear between the TUG master, POAC and both vessel Masters.

10.?As a Master, assign roles and responsibilities to your crew and above all request for their attention and vigilance. The Master has only 2 eyes available. He should be assisted by his crew in case something irregular is observed. In order to receive such assistance, the crew should be aware of key elements and causal factors that may address increased risk. So consider in establishing a short safety meeting with your crew members!

11.?Make sure that the crew is fatigue free, especially during consecutive STS operations.

12.?Study that the weather conditions will be suitable for the STS operation. Limitations from weather conditions are imposed to fender selection, rolling of vessels, loads on mooring lines but above all, uncontrolled stress to the deck crew. Such crew stress could become fatal during their actions or during of proper assessment of the situation. In some STS locations, weather limitations are imposed from the local administration. Those should become known to the Master from the STS organiser, charterer, or local agent.

13.?During the Safety meeting with the POAC and the participating Master, discuss possible thresholds that will trigger the postponement of the berthing operation. For example, if the STS berthing operation takes place while Mother ship is at anchor, the approaching pattern should have been agreed by both Masters and POAC and should be constantly be assessed through the ECDIS. In case of any doubts the STS operation should be abandoned and thereafter be rescheduled.

14.?As a Master of the Mother vessel, assess that fenders are in correct position on the manoeuvring vessel when she approaches. At this stage, the Master assess and confirms at checklist No. 3 that fenders are according to the agreed position as denoted at the JPO.

15.?Ensure that the crew of the participating vessel has received a proper training similar to the one delivered to your crew.

16.?During mooring and un-mooring operation, ensure that mooring lines are secured/ released with the correct order.

17.?Conduct a relevant drill prior to the STS operation. Your technical operator may assist you in this respect with drills between shore and the vessel.

18.?Request a confirmation C from the service provider that the assigned POAC has received STS training in a simulator and he has understanding on the hydrodynamic Ship interaction effect in underway STS mooring operations.

OnlineSTS.net member vessels apply a diligent approach on each?STS operation, when consultancy is requested by their Managers, with specific technical guidance to Masters. Statistics on vessel steel to steel contact, reveal a percentage of about 0.33% of the conducted operations as of today (12/09/2016) for member vessels and for Global STS locations. A detailed statistical analysis may be adopted for specific locations. The culture addressed by the services aims in empowering?Masters' confidence for the operation through dedicated advice and past performance data.

For more information on this circular please contact us.

?